The differential photoacoustic method combines the sensitivity of photoacoustic spectroscopy with the long absorption path length used by conventional absorption spectroscopy and allows open-path and flow-through detection of gases.

TECHNOLOGY PRINCIPLE

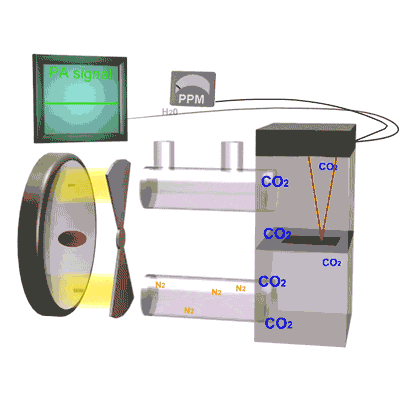

The differential system is composed of three separate gas cells: a sample cell, a reference cell, and a differential photoacoustic cell. The sample cell holds the gas to be analyzed, while the reference cell is filled with a non-absorbing zero-gas, such as nitrogen. The differential photoacoustic cell contains the gas to be analyzed, typically at higher concentrations. This differential cell is divided into two equal halves, separated by Gasera’s ultra-sensitive cantilever sensor.

The light emitted by the source is split into two equal beams. The top beam passes through the sample cell and enters the top half of the differential cell, while the bottom beam passes through the reference cell and enters the bottom half. When the sample cell contains no absorbing gas, both beams reach the differential cell with equal intensity, generating identical pressure waves in the top and bottom halves that cancel each other out.

If the sample cell absorbs light, however, a net pressure effect develops in the differential cell. This pressure difference is detected by the silicon cantilever sensor, with the cantilever displacement directly proportional to the concentration of gas in the sample cell. Because the sample cell is separate from the photoacoustic detection cell, open-path measurements can be performed with minimal interference from ambient noise.

The IR source can be a blackbody, an LED, or a laser. Modulation can be achieved either with a mechanical chopper or by electrically modulating the source. One of the key advantages of this technique is that no optical filter or spectrograph is needed, as the gas inside the differential cell itself acts as an optical filter—a concept known as the gas correlation method. The selectivity is determined by the actual absorption spectrum of the gas and is unaffected by the instrument’s characteristics.

APPLICATIONS

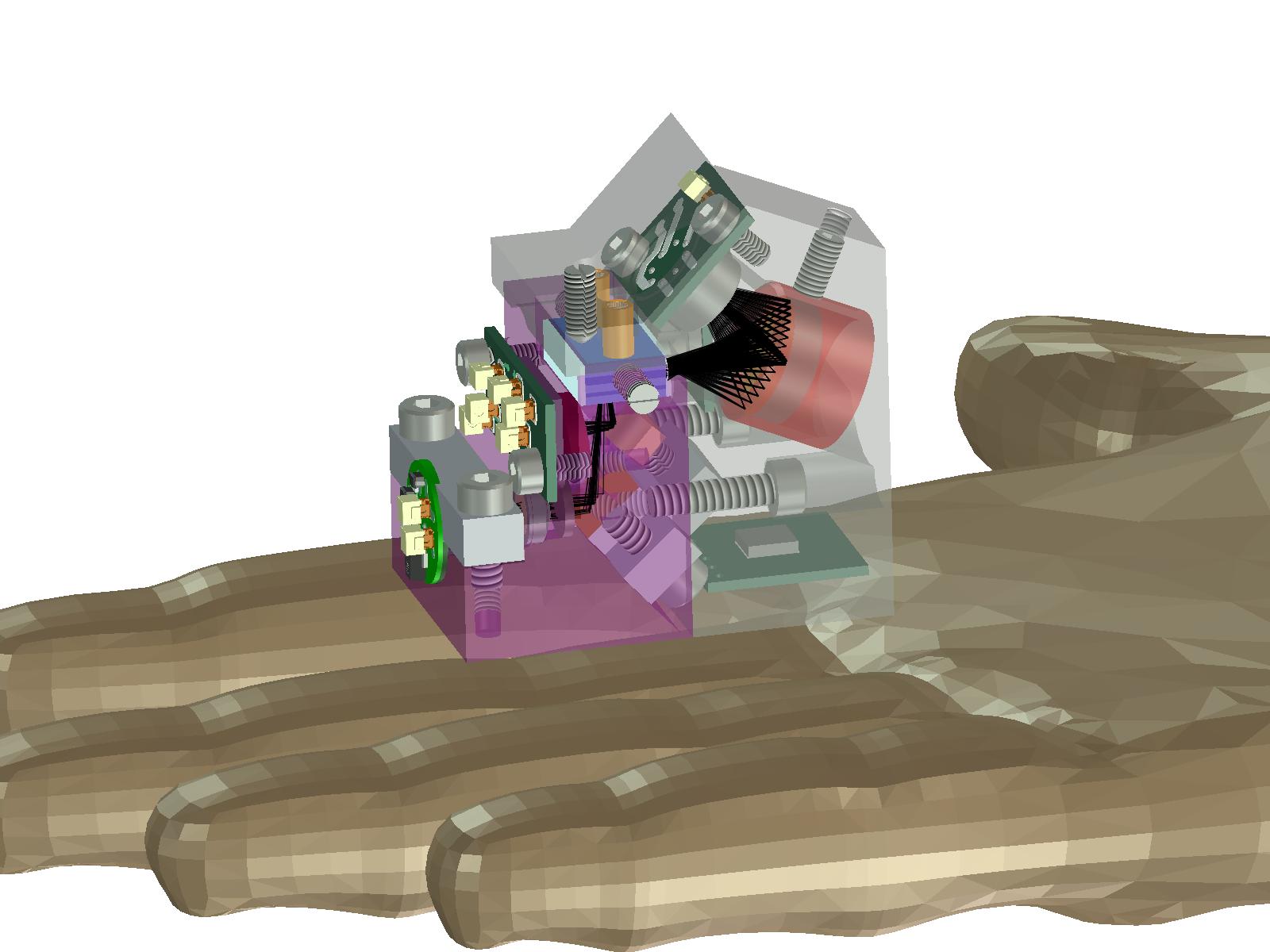

Differential photoacoustic spectroscopy provides an ideal platform for single-gas sensors. This measurement concept forms the basis of the MINIGAS EU project, which aims to develop a miniaturized, high-performance gas sensor by combining cantilever-based differential PAS with infrared LED sources.

By pairing laser sources with the differential photoacoustic spectroscopy concept, a fast and highly sensitive gas analyzer can be realized. This approach is particularly well suited for applications such as gas flux measurements, where both low detection limits and rapid response times are essential.